Root shielding gas for improved corrosion

Root shielding gas is commonly used for welding stainless steel, but why is it so important and what function does it serve? Herbert Nilsson, one of AGA¡¯s welding experts explain more.

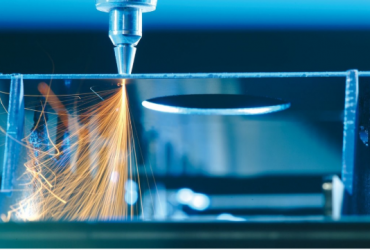

Welding stainless steel is mostly similar to welding other types of steel but there are some key differences. One of the most important is the type of shielding gas used. Stainless steel is sensitive to temperatures of 250 °C or more. When these temperatures occur without an inert gas shield, it causes the surface to oxidise, resulting in reduced corrosion resistance. If the stainless steel surface is not protected from the oxygen in the air, the root surface will oxidise as a joint. This is why a protective inert root shielding gas must be used.

Fact box:

3 steps

- Remove any trapped air

- Maintain an inert gas atmosphere during welding

- Continue to maintain the atmosphere until the temperature has dropped below 250 grader Celsius

Inert gas atmosphere

The process for achieving a good level of root protection can be divided into three key steps: the first step is to remove any trapped air before welding, the second is to maintain an inert gas atmosphere during welding and the third step is to continue to maintain this atmosphere after welding, until the temperature has dropped below 250 °C again.

In order to reduce the oxygen content from 21 per cent in the ambient air to values as low as 25 ppm of residual oxygen in a tube that is going to be welded, the tube needs to be flushed out with a root shielding gas until there is no oxidation on the inside. The tube will need to be flushed repeatedly before it will have an oxide-free root surface with the same corrosion resistance as the rest of the tube.

Continuous gas flow

After flushing, the gas flow can be reduced to maintenance levels during welding. However, Nilsson emphasises that the flow of gas from the cylinder needs to be monitored before, during and after welding. For this, a two-stage gas regulator with flow tubes that maintain a constant gas flow should be used.

The most common root shielding gases include pure argon, which is a totally inert gas, pure nitrogen gas, and Formier10, which is a mixture of nitrogen and 10 per cent hydrogen. The latter is most effective as the hydrogen gas reduces the residual oxygen, thereby minimising oxidation of the root surface.

By: Herbert Nilsson, Illustration: Shutterstock